Application of a Magnetic Filter

Magnetic fine filtration of process fluids is particularly suited to filtration of fluids with particles from grinding and cast iron processing. The magnetic filter has various applications such as coolants, grinding fluids, washing fluids up to 80°C and other fluids with ferritic particles. A magnet filter is often used in combination with BELKI deep bed band filters or central systems.

Operation of a Magnetic Filter

The magnetic belt / band filter is fully automatic and only has to be set at startup. The magnetic field is created by permanent magnets, and therefore no energy has to be used to establish a magnetic field. The forwarding of the band occurs in intervals as the particles build up to a certain level. The extremely strong permanent magnets create a strong magnetic field which ensures filtration of very fine particles down to under 10 μm. The forwarding intervals are set so that the particles will have the necessary drying time before leaving the magnetic filter. The filter cake is removed on the manual magnetic filter (3.10 M) by using a scraper.

Advantages of a Magnetic Filter

- Filtration of the very fine particles extends the lifetime of the process fluid and protects nozzles, valves and rotating clutches in processing machines

- Filtration occurs without any use of consumables and the unit has low energy consumption

- The filter has a high degree of filtration and high capacity

- Effective for cast iron particles as the graphite particles tie to the ferrite

- Designed in stainless steel

- By fully automatic magnetic band / belt filters (model 3.10 A, 5.13 A and 7.20 A) the forwarding intervals can be adjusted, ensuring that the filter cake has the necessary drying time and dry sludge is easier and cheaper to dispose of

How can we help you?

Are you looking for a magnetic filter that is suitable for your requirements? Should it be a fully automatic solution or is the manual solution sufficient? Our competent team is always ready to advise you on magnetic filtration and to answer your questions. Please do not hesitate to contact us...

Working principle of Magnetic Filter

Range of Magnetic Filters

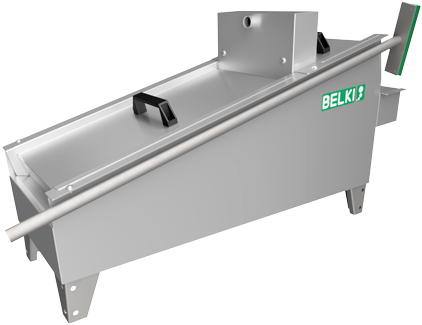

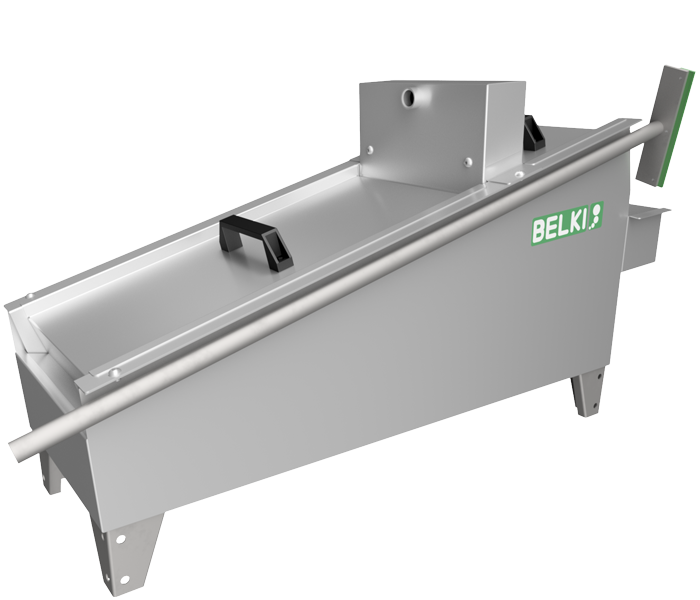

BELKI's manual magnetic filter 3.10M is the solution for filtration of ferritic fine particles from process fluids. This version is designed for up to 200 l/min. The magnetic filter is also available with higher capacity. Equipped with powerful neodymium magnets, optimum filter purities are achieved. The filter cake is manually scraped into a sludge container with a scraper.

Manual magnetic filter 3.10M

T14-000-000

Read more

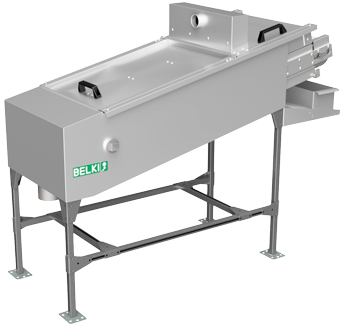

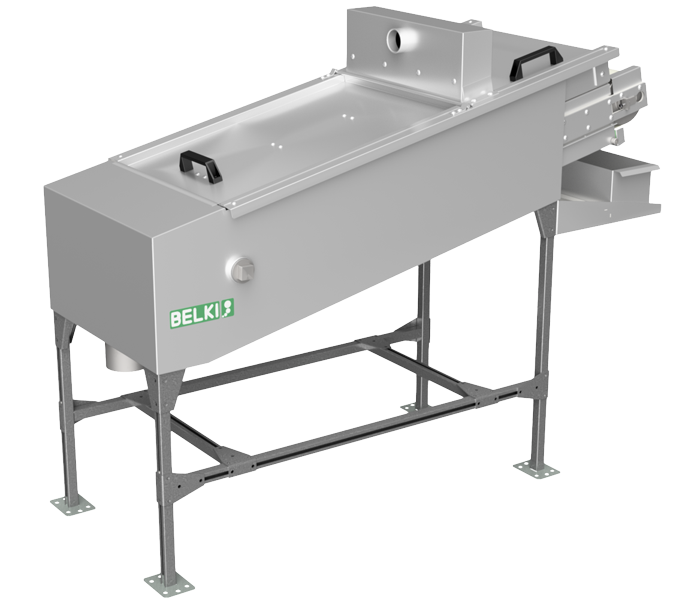

BELKI's automatic magnetic belt filters are the solution for the filtration of ferritic ultra-fine particles with high sludge volumes. The process fluids are usually filtered in by-pass. Depending on the medium, up to 1000 l/min can be filtered with the automatic magnetic belt filter. Suitable for use on grinding machines, machine tools, washing systems and central systems, among others.

Automatical magnetic belt filter 3.10A / 5.13A / 7.20A

T67-210-000 / T67-510-000 / T67-100-000

Read more

Technical specifications for Magnetic Filters

| Type | Item nummer | Capacity (l/min) | Material | Connection (V/Hz) | Weight (kg) | Length (mm) | Width (mm) | Height (mm) |

|---|---|---|---|---|---|---|---|---|

| 3.10M | T14-000-000 | 200 | EN1.4301 | - | 52 | 1081 | 383 | 526 |

| 3.10A | T67-210-000 | 250 | EN1.4301 | 3x400/50 | 52 | 1404 | 427 | 806 |

| 5.13A | T67-510-000 | 500 | EN1.4301 | 3x400/50 | 80 | 1595 | 627 | 816 |

| 7.20A | T67-100-000 | 1000 | EN1.4301 | 3x400/50 | 155 | 2902 | 961 | 912 |