Application of an Oil Separator

The BELKI Oil Separator is applied for removal of tramp oil and other surface contaminants from process fluids, e.g. coolants and degreasers. The BELKI Oil Separator is utilised as a fixed installation or mounted on a trolley for maintenance of any number of tanks.

Operation of an Oil Separator

The surface is skimmed by a self-regulating suction unit called tilting skimmer. The slow revolving, electrically driven diaphragm pump is designed to keep the tramp oil from being mixed into the fluid, thereby ensuring an effective separation. The tramp oil flows to a collecting container and the cleaned fluid flows back to the machine tank.

Advantages of an Oil Separator

- Self-regulating suction unit (tilting skimmer), only skimming the surface

- The suction unit compensates for level variations in the tank

- Gentle operation of the pump, ensuring effective oil separation

- Easily adjustable so that only the oil is flowing to the oil container

- The oil container has decantation function

- Possibility for connection of several suction units (dependent on model type)

211 H max 1 pcs. / 321 and 60 S max 2 pcs. / 200 LS max 4 pcs. - Module constructed; oil separator and pump can be mounted separately

(for 60 S and 200 LS) - The models 211H and 321 can, like the 60S, be delivered in a mobile version that can easily be moved between several machines

How can we help you?

Are you looking for a type of oil separator which is suitable for your requirements? Or do you have any questions about the size and function of the tilting skimmer? Our competent team is always ready to advise you on oil separation and to answer your questions. Please do not hesitate to contact us...

Working principle of an Oil Separator

Range of Oil Separators

Type 211H is the best selling BELKI oil separator. With a capacity of 25 l/h this oil separator is the ideal solution for use on tooling machines such as CNC machines, turning and milling centres and smaller washing machines. The type 211H enables an effective cleaning of bath surfaces up to 2 m². The removal of the oily medium is carried out by an individual tilting skimmer.

Oil separator 211H

T21-211-700

Read more

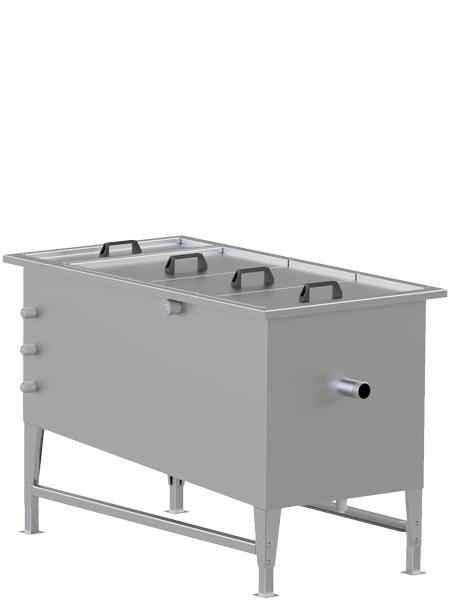

Type 331 is a universally applicable oil separator. With a capacity of 150 l/h, this oil separator is the optimal solution for use on tooling machines such as CNC machines, turning and milling centres and washing machines. The type 331 allows an effective cleaning of bath surfaces up to 5 m². Two tilting skimmers can be connected to type 331 and with a trolley the oil separator is mobile.

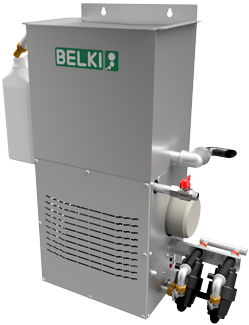

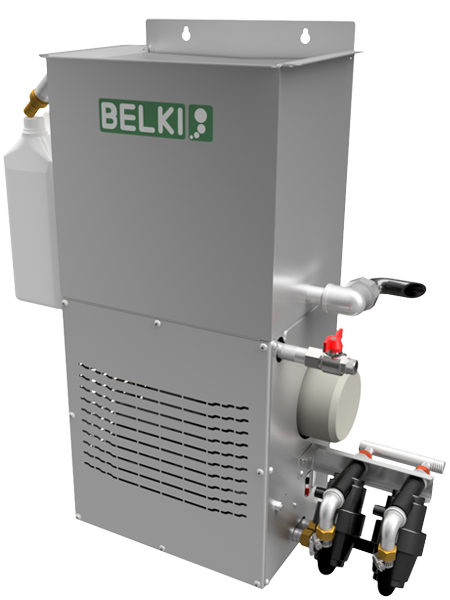

Oil separator 331

T206-331-230 / T206-331-400

Read more

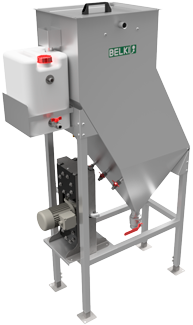

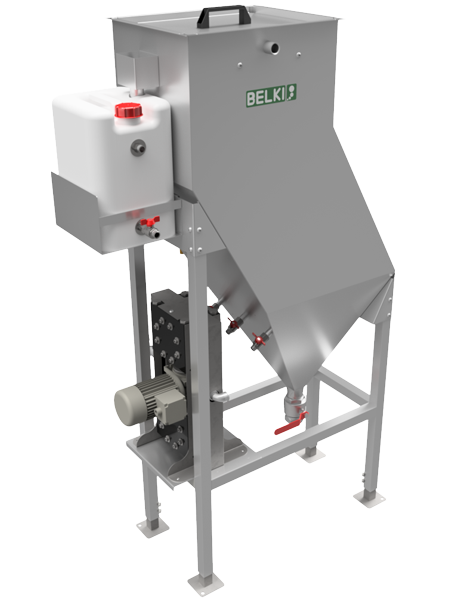

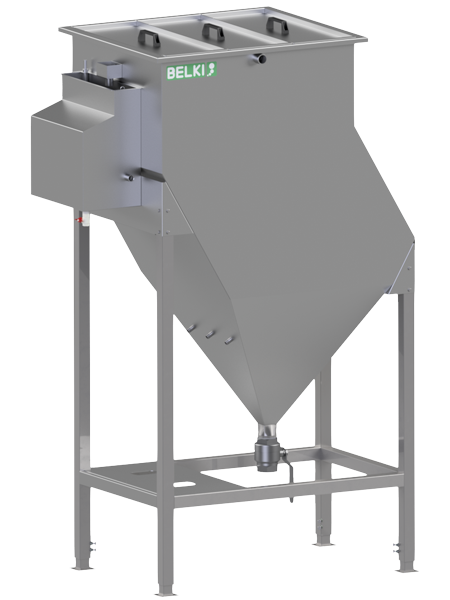

Type 60S is BELKI's smallest coalescence separator. With a capacity of 300 l/h this oil separator is the suitable solution for use on tooling machines such as CNC machines, turning and milling centres as well as washing machines with high oil loads. Available in mobile or stationary design. With the type 60S bath surfaces up to 15 m² can be cleaned effectively with two tilting skimmers.

Oil separator 60S

T04-060-260 / T04-060-400

Read more

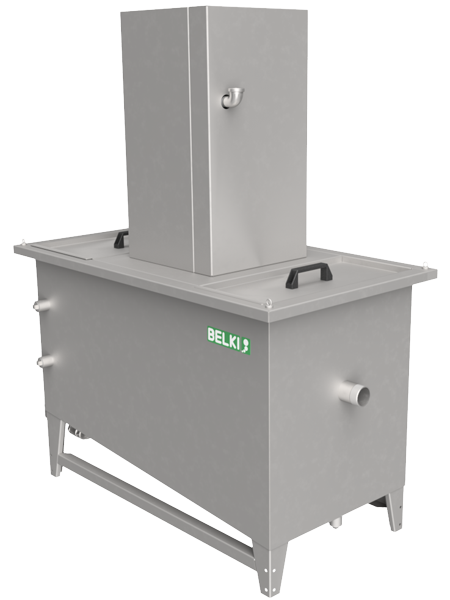

Type 200LS is BELKI's standard coalescence separator. With a capacity of 600 l/h, this oil separator is the right solution for use on tooling machines such as CNC machines, turning and milling centres, centralized systems up to 10 m³ and washing machines with emulsified oil loads. Bath surfaces up to 25 m² can be effectively cleaned. The quattro pump allows the connection of up 4 tilting skimmers.

Oil separator 200LS

T62-002-000

Read more

Type 500LS is BELKI's most powerful coalescence separator. With a capacity of 1200 l/h, this oil separator is the perfect solution for use on large tooling machines such as CNC machines, turning and milling centres, washing machines and central systems. Individual pump solutions are available for the 500LS. The coalescence separator type 500LS is designed for bath surfaces up to 50 m².

Oil separator 500LS

T59-010-100

Read more

Type 1000LS is BELKI's high-performance oil separator with coalescence stage. With a capacity of 2400 l/h, this oil separator is the perfect solution for use on large machine tools as well as special systems and centralized systems. Individual pump solutions are available.. The oil tank is made of stainless steel as standard. The coalescence separator is designed for bath surfaces up to 100 m².

Oil separator 1000LS

T225-000-000

Read more

Type 200LV is BELKI's solution for cleaning surfaces with floating chips and foam. Equipped with a vacuum pump, bath surfaces up to 25 m² can be effectively cleaned with a capacity of 600 l/h. Thanks to the vacuum technology, this oil separator is extremely low-wear with very limited maintenance on tooling machines and washing systems.

Oil separator 200LV

T231-000-200

Read more

The BELKI oil separator 500LV represents BELKI's special solution for the separation of oil from highly foamy and oil-contaminated systems. With a capacity of 1200 l/h, this oil separator is the right solution for bath surfaces up to 50 m². Individual surface suction and pump technology guarantee effective cleaning on large tank systems of tooling machines and washing systems.

Oil separator 500LV

T291-500-000

Read more

The BELKI oil separator 2000LV represents BELKI's special solution for oil separation from systems with a high foam and oil content. With a capacity of 8000 l/h, this oil separator is the optimum solution for bath surfaces up to 100 m². Surface suction and pump technology individually designed guarantee effective cleaning on large tank systems of tooling machines and washing systems.

Oil separator 2000LV

T362-000-000

Read more

The BELKI oil separator 10000LV is BELKI's largest special solution for the separation of oil from highly foamy and oil contaminated systems. With a capacity of 13440 l/h this oil separator is the ideal solution for bath surfaces up to 170 m². Individual surface suction and pump technology guarantee effective cleaning on large tank systems of tooling machines and washing systems.

Oil separator 10000LV

T322-000-210

Read more

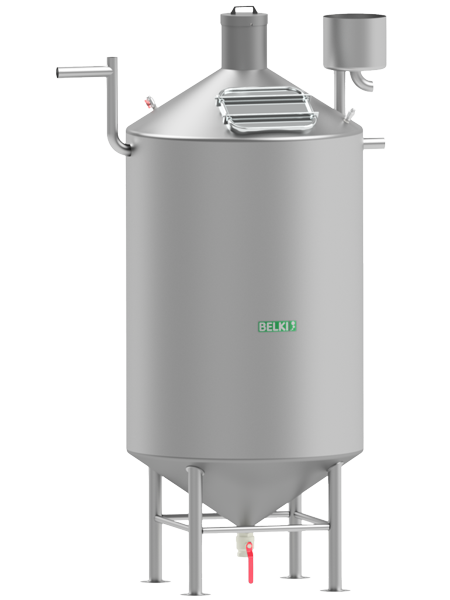

BELKI Oil Separator for the food industry is used for pre-separation of wastewater from e.g. fish processing, where it is desired to reduce the oil content in the wastewater, for separate disposal or further processing. The separator has a total volume of 4 m³ and can separate up to 8 m³ of waste water per hour. The oil separator is prepared for connection to CIP systems.

Oil Separator for the food industry

T366-500-000

Read more

Technical specifications for Oil Separators

| Type | Item nummer | Capacity (l/h) | Surface (m²) | Oil container (l) | Connection (V/Hz) | Consumption (W) | Material | Weight (kg) | Length (mm) | Width (mm) | Height (mm) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 211H | T21-211-700 | 25 | 1-2 | 2,5 | 230 | 6 | EN1.4301 | 12,5 | 410 | 235 | 560 |

| 321 | T206-321-230 / T206-321-400 | 150 | 5 | 5 | 230/3x400/50 | 250 | EN1.4301 | 36 | 682 | 268 | 794 |

| 60S | T04-060-230 / T04-060-400 | 300 | 15 | 20 | 230/3x400/50 | 250 | EN1.4301 | 57 | 730 | 445 | 1065 |

| 200LS | T62-002-000 | 600 | 25 | 20 | 3x400/50 | 250 | EN1.4301 | 100 | 1075 | 471 | 1867 |

| 500LS | T59-000-000 | 1200 | 50 | 20 | 3x400/50 | 250 | EN1.4301 | 250 | 1325 | 604 | 2110 |

| 1000LS | T225-000-000 | 2400 | 100 | 20 | 3x400/50 | 500 | EN1.4301 | 380 | 1626 | 950 | 2543 |

| 200LV | T231-000-200 | 1000 | 40 | 40 | 3x400/50 | 250 | EN1.4301 | 155 | 1260 | 710 | 1610 |

| 500LV | T291-500-000 | 1200 | 50 | 50 | 3x400/50 | 500 | EN1.4301 | 140 | 1509 | 805 | 1035 |

| 2000LV | T362-000-000 | 8000 | 100 | 1000 | 3x400/50 | 250 | EN1.4301 | 560 | 2100 | 1100 | 1130 |

| 10000LV | T322-000-210 | 13440 | 170 | 1650 | 3x400/50 | 250 | EN1.4301 | 1448 | 3200 | 1500 | 2800 |

BELKI Oil Separators, prices and costs

BELKI offers a wide range of stainless steel oil separators. The prices and costs of these oil separators depend strongly on the performance class of these devices as well as the required accessories.

The costs for a BELKI oil separator may be a little higher than those of other suppliers, but for us and the users of our technology, the high quality of the oil separators in terms of material and usability is important. BELKI oil separators are made of stainless steel with very smooth surfaces which offer little or no opportunities for microorganisms to attach to. After purchasing one of our oil separators you do not need any consumables, only wear parts such as the diaphragm set, which has to be replaced from time to time.

For information on prices, costs and performance parameters of BELKI oil separators please contact our team or use the contact form "Contact us". We are looking forward to help you.

FAQ about Oil Separators

Oil separation

I want to buy an oil separator

BELKI offers a wide range of oil separators in many price categories. The cheapest models are oil skimmer / belt skimmer. These skimmers can remove oil from tanks with small surfaces and limited space. The more efficient oil separators are used for surfaces of liquids from 1 m² and are accordingly slightly more expensive. The BELKI oil skimmers and oil separators are all made of stainless steel, which guarantees a long life time of the separator. For concrete offers please please contact our team or use the contact form "Contact us".

How does an oil separator work?

A BELKI oil separator works by the principle of gravity. The fluid surface is sucked off by a self-adjusting suction unit, a so-called tilting skimmer. The fluid is conveyed into the oil separator by a slow-running, electric diaphragm pump. The pump conveys so gently that no oil droplets are fragmented in the pump chamber. In the oil separator the oil separates very quickly from the aqueous fluid. The oil runs into a collecting tank and the cleaned fluid runs back into the machine tank. In this way, tramp oils from process fluids such as cooling lubricants, degreasing baths and other fluids with tramp oil are effectively separated by the oil separator.

Separation and filtration of oil

What are the costs of an oil separator?

BELKI offers a wide range of oil separators starting in the price range from 660 €. The cheapest models are oil skimmer / belt skimmer. These skimmers can remove oil from tanks with small surfaces and limited space. The more efficient oil separators are used for surfaces of liquids from 1 m² and are accordingly slightly more expensive. The BELKI oil skimmers and oil separators are all made of stainless steel, which guarantees a long life time of the separator. For concrete offers please please contact our team or use the contact form "Contact us".

What is an oil skimmer?

An oil skimmer is a cheaper and more compact alternative to an oil separator. The oil skimmer / belt skimmer is used for oil separation from tanks with very small surfaces and limited space. The oil is removed from the bath surface by slow running, high quality teflon belts. Depending on the type of oil skimmer, the oil is decanted either via an integrated 2.5 l collection tank or a stainless steel collection tray, which works like an oil separator. In this way, process fluid that is also discharged is returned to the tank; the oil remains in the collection tank.